An immersion heater is an electric heating apparatus designed to submerge a bundle of tubular heating elements in a tank or container to heat a liquid. These liquids can include water, oils of varying viscosities, solvents, process solutions, liquid chemicals, or even gases. The purpose of the heater is to provide direct contact heating, enabling quick and controlled increases in temperature. This method is often used to maintain specific properties like temperature, viscosity, pressure, solubility, or miscibility—parameters that are critical for efficient industrial processing.

As an immersion heater manufacturer for oil and gas industry, LOOM GRID ensures that its immersion heaters are essential components in industries like oil and gas, as well as a range of other sectors that rely on efficient and reliable heating. From massive storage tanks in oil refineries to delicate processing environments in pharmaceuticals, immersion heaters are the backbone of temperature management. Their ability to deliver quick, direct heat allows companies to meet precise temperature requirements swiftly, no matter the type of heater—whether it’s pipe, circulation, or over-the-side immersion heaters.

Immersion Heaters in Critical Industries

While immersion heaters are integral to many industries, their role is particularly pronounced in sectors where fast and effective heating is paramount. These heaters excel in cold climates where fluids need protection from freezing, and maintaining a steady flow of liquids becomes a challenge. During winter months, these heaters ensure fluids, especially those in external pipelines or storage tanks, do not freeze, which can disrupt operations.

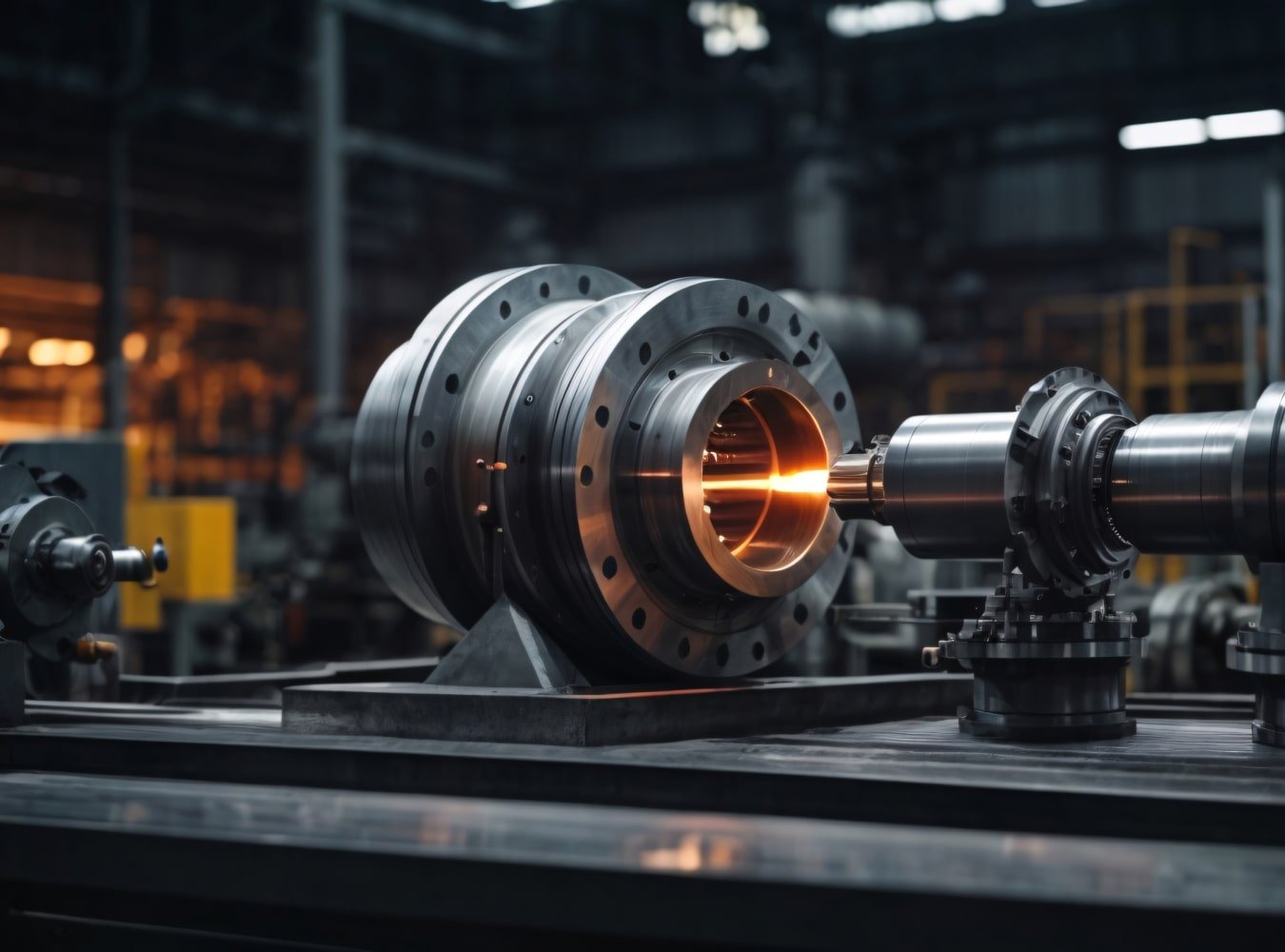

For instance, LOOM GRID’s flanged immersion heaters, equipped with ANSI-rated flanges and tubular elements, offer customized heating solutions for industrial environments. As a process immersion heaters manufacturer in India, LOOM GRID ensures that industries, particularly oil and gas, benefit from products designed specifically for their needs. The use of thermowells, which protect sensitive components like RTDs (Resistance Temperature Detectors), thermostats, or thermocouples, ensures that temperature readings are accurate and that the connected digital controllers can maintain the desired process temperatures with precision.

Applications Across Multiple Sectors

LOOM GRID’s immersion heaters serve numerous applications, ranging from freeze protection to process temperature control, viscosity management, steam generation, and chemical reactions. These heaters are widely used by industries like oil and gas, water treatment, agriculture, power generation, construction, transportation, and mining. As an immersion heater manufacturer for oil and gas industry, LOOM GRID is committed to providing reliable, durable, and highly efficient products that meet the stringent requirements of modern industry.

As a leading process immersion heaters manufacturer in India, LOOM GRID ensures that its products not only perform efficiently but also provide solutions that are versatile enough for various industries. The heaters’ ability to meet the precise demands of these industries makes them indispensable.

LOOM GRID: Standard and Custom Immersion Heater Designs

LOOM GRID offers both standard and custom immersion heater designs, ensuring that clients receive solutions tailored to their specific needs. The company’s design and application teams work closely with clients to produce optimized heater configurations for various industrial applications. Whether it’s a large-scale oil processing plant or a water treatment facility, LOOM GRID, as a process immersion heaters manufacturer in India, offers heaters built to meet the most stringent requirements.

Key Considerations When Choosing an Immersion Heater

When selecting an immersion heater, the following specifications are critical to ensuring optimal performance:

- Heater Styles: The mounting and fitting options should be compatible with the container being used. Options include flanged, screw plug, or over-the-side heaters.

- Sheath Materials: The material of the tubular heating elements needs to be corrosion-resistant and suitable for the operating temperature. Common choices include Incoloy or stainless steel.

- Terminal Housing and Enclosures: Depending on the environment, choose from explosion-resistant, flameproof, liquid-tight (IP66), or general-purpose enclosures.

- Watt Density/Power Density: Watt density should be selected based on the medium being heated to prevent surface scorching or carbonization.

- Total Power Output: The total power required depends on the volume of the container and how quickly the temperature must rise during startup.

- Dimensional Considerations: The heater should be sized and shaped according to the dimensions and features of the tank or container.

- Control Systems: A thermostat or more advanced industrial control panels are often recommended to achieve precise temperature control.

As a key immersion heater manufacturer for oil and gas industry, LOOM GRID provides comprehensive support for companies looking to integrate advanced heating systems into their operations.

LOOM GRID: The Benefits of Process Immersion Heaters

LOOM GRID’s immersion heaters offer many advantages for industries that rely on efficient heating systems:

- Efficient Heat Transfer: These heaters are virtually 100% efficient, as the elements are directly submerged in the liquid, ensuring minimal heat loss.

- Eco-Friendly Solutions: As a process immersion heaters manufacturer in India, LOOM GRID produces green thermal energy without generating pollutants or residual discharge.

- Safety Features: Built-in safety mechanisms, such as ground fault protection and ingress protection, protect personnel from electrical hazards and fire risks.

- Precise Temperature Control: When fitted with advanced controllers, these heaters ensure stable and safe process management, particularly when working with flammable materials.

- Long Service Life: LOOM GRID’s heaters are designed for durability, provided they are used within their intended parameters and maintained regularly.

- Cost-Effective Solutions: The company’s engineering team designs optimized systems that minimize upfront investment costs while maximizing operational efficiency.

- Compliance with Industrial Standards: All LOOM GRID products adhere to stringent industry regulations, ensuring both safety and sustainability in their design.

Field Services and Support

As an immersion heater manufacturer for oil and gas industry, LOOM GRID offers a wide range of field services, including system installation assistance, startup support, training on operations and maintenance, and regular inspections. This level of customer service ensures that heater systems operate smoothly and that any necessary adjustments can be made on-site, such as wiring modifications. LOOM GRID’s commitment to customer satisfaction is evident in their comprehensive support offerings, making them a trusted partner in heating solutions.

Electric vs. Fuel-Fired Heaters: Efficiency and Environmental Considerations

In the oil and gas industry, many heating systems still rely on fuel-fired units, particularly in oil/water separation processes. However, there is a growing trend towards replacing these units with electric immersion heaters, especially in smaller-scale applications. Electric heaters provide several benefits, including reduced local emissions and increased operational uptime.

LOOM GRID immersion heaters offer two primary heating methods: direct and indirect immersion. In direct immersion, heating elements are submerged directly into the fluid, ensuring maximum heat transfer efficiency. As a process immersion heaters manufacturer in India, LOOM GRID ensures that both direct and indirect heaters provide the industry with eco-friendly and efficient alternatives to fuel-fired systems. In either case, replacing fuel-fired heaters with electric models can provide significant benefits, particularly for companies looking to reduce emissions, improve safety, and lower operational costs.

As an immersion heater manufacturer for oil and gas industry, LOOM GRID continues to innovate in the design and implementation of immersion heaters, ensuring that our products meet the evolving needs of industries worldwide.