Refining crude oil demands significant heat, with precise temperatures determining the production of various petroleum products. Central to this process are circulation heaters, also known as inline circulation heaters, which are essential for maintaining the required temperature ranges. These heaters play a vital role in optimizing performance in refineries, production platforms, and pipeline operations. When selecting the right “circulation heaters manufacturer for oil and gas industry,” companies can ensure their operations are efficient and safe.

This article will explore circulation heaters in depth, explain their working principles, and highlight their critical role in the oil and gas industry. By understanding these basics, you’ll appreciate how “circulation heaters manufacturer for oil and gas industry” and “circulation heater manufacturer for fluid heating” contribute to the efficiency and safety of industrial processes.

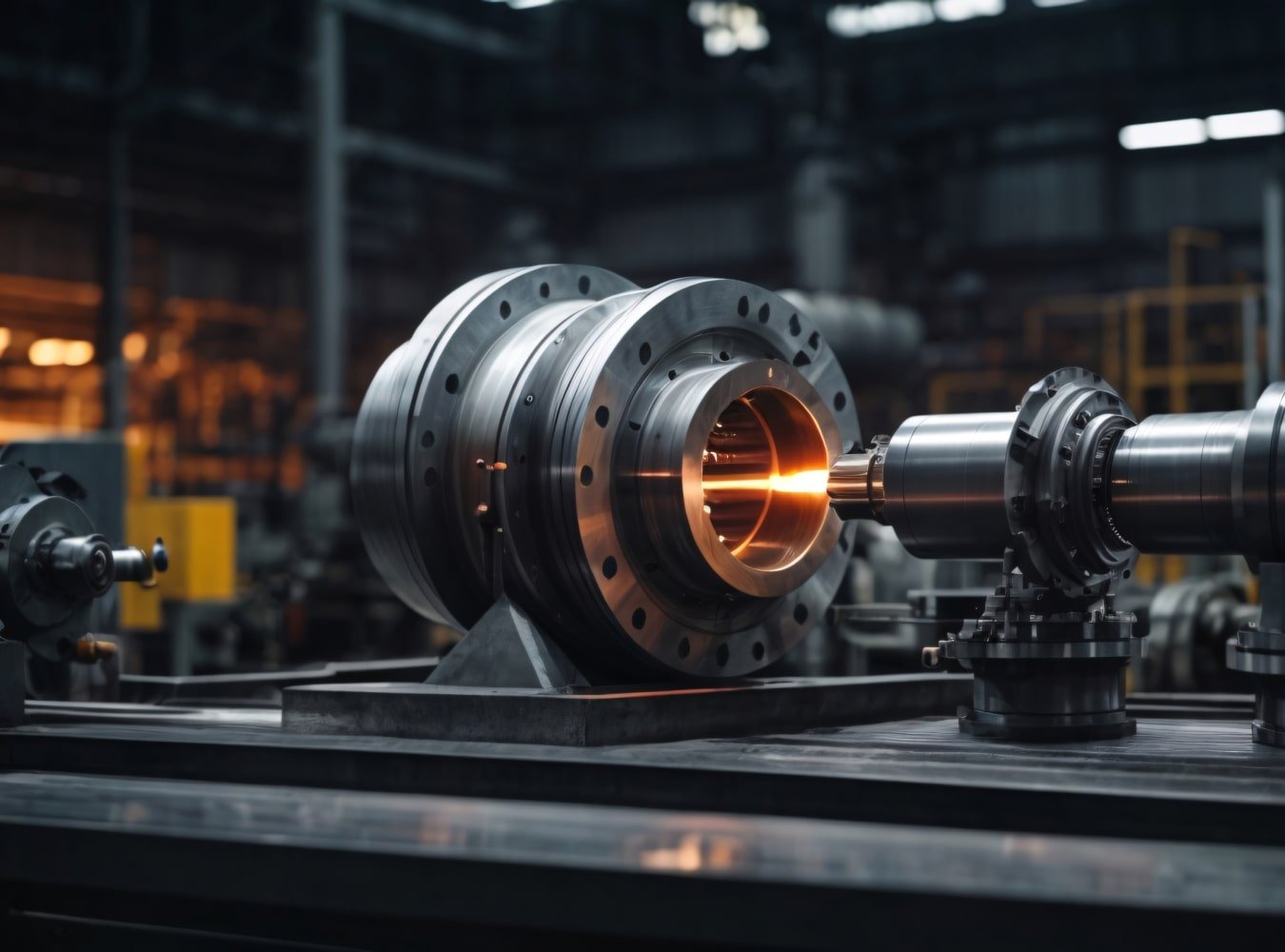

Understanding LOOM GRID Circulation Heaters: The Basics and Beyond

Various types of electric process heaters exist, but circulation heaters stand out due to their ability to heat a flowing liquid or gas continuously. These heaters consist of three main components:

- Heating Element: The heating element, typically made from high-quality materials such as Incoloy, stainless steel, or copper, converts electrical energy into heat. Some systems may also use gas-fired or steam elements for heating.

- Control Panel: The control panel manages the entire heating process. It communicates with sensors to ensure accurate temperature control, safeguarding the heater and preventing overheating or inefficiencies.

- Temperature Sensors: Sensors continuously monitor the fluid’s temperature. If the temperature deviates from the set point, the control system adjusts the heating element’s output to bring it back to the desired range.

LOOM GRID circulation heaters excel in delivering uniform and precise heat, even in extreme industrial environments. These heaters are capable of reaching temperatures as high as 1,200°F, heating oils, gases, or air without causing damage. Whether for small-scale high-purity gas streams or large-scale liquid flow systems operating at 5,000 PSI, LOOM GRID heaters ensure reliable and safe operation. This is why many operators turn to the right “circulation heaters manufacturer for oil and gas industry” or the right “circulation heater manufacturer for fluid heating.”

How LOOM GRID Inline Oil Heaters Work

The working principle of LOOM GRID inline oil heaters is straightforward yet effective. Here’s a breakdown of the process:

- Oil Flow: Oil is pumped into the heater through an inlet and flows through a system of pipes or tubing.

- Heating Element: Inside the heater, a resistance-based heating element, typically constructed from high-resistance alloys such as stainless steel or Incoloy, heats the oil.

- Electrical Current: The heater operates on high-voltage electrical currents, typically ranging from 110 to 690V. Power capacities can reach up to 5000kW, making them suitable for large industrial operations.

- Heat Transfer: As the oil passes over the heating element, heat is transferred to the oil through conduction, raising its temperature.

- Temperature Control: A sophisticated temperature control mechanism ensures the oil remains at the desired temperature. The system includes sensors that monitor the oil’s temperature and adjust the heating element’s power output as needed.

- Thermostat: The thermostat provides an additional layer of temperature control, turning the heater on or off based on preset parameters.

- Outlet: After heating, the oil flows out of the heater and continues through the processing system, maintaining the required temperature for the next stages of refinement.

- Safety Features: LOOM GRID inline heaters come equipped with built-in safety measures, such as temperature limit switches, pressure relief valves, and thermal cut-offs, to prevent overheating and ensure the system’s integrity.

In summary, LOOM GRID circulation heaters provide a reliable, efficient, and safe way to heat oil through a controlled and regulated process, which is critical for industrial applications. Consulting a “circulation heaters manufacturer for oil and gas industry” or “circulation heater manufacturer for fluid heating” will ensure the equipment is tailored to your needs.

The Importance of Inline Oil Circulation Heaters

Inline heaters serve two primary functions in the oil and gas industry:

- Separation of Crude Oil Products: Heat plays a crucial role in refining crude oil by separating its various components based on their boiling points. For example:

- 20°C: Butane and propane

- 150°C: Gasoline or petrol

- 200°C: Kerosene

- 300°C: Diesel

- 370°C: Diesel

- 400°C: Asphalt, paraffin wax, and lubricating oil

- Preventing Hydrate Formation: Hydrates are solid, ice-like substances that form in petroleum pipelines at high pressures and low temperatures. If unchecked, hydrates can block pipelines, leading to costly disruptions. LOOM GRID heaters maintain elevated temperatures to prevent hydrates from forming, ensuring the smooth and efficient operation of oil transport systems.

Additionally, heating oil reduces its viscosity, making it easier to pump through pipelines. LOOM GRID heaters not only enhance operational efficiency but also prevent potential bottlenecks or malfunctions caused by high-viscosity fluids. For this reason, the right “circulation heaters manufacturer for oil and gas industry” is essential for ensuring high-performance equipment.

Benefits of LOOM GRID Circulation Heaters in Oil and Gas Operations

The advantages of using LOOM GRID circulation heaters in the oil and gas industry are numerous:

- Improved Process Efficiency: Continuous heating ensures that the oil remains at the optimal temperature for refining and transportation.

- Consistent Temperature Maintenance: Accurate temperature control minimizes the risk of system failures, preventing overheating or inefficient energy use.

- Enhanced Safety: LOOM GRID heaters are designed with built-in safety features to prevent damage to both the equipment and the oil being heated.

- Minimal Maintenance: LOOM GRID heaters operate with little maintenance, reducing operational costs and maximizing profitability.

To ensure these benefits, it’s vital to select a reliable “circulation heater manufacturer for fluid heating” or “circulation heaters manufacturer for oil and gas industry” that understands the specific requirements of your operations.

Real-World Applications of LOOM GRID Circulation Heaters

LOOM GRID circulation heaters are utilized at various stages of petroleum processing, from production platforms to refineries and shipping terminals. Common applications include:

- Oil Pumping Stations: Heaters reduce the oil’s viscosity, making it easier to pump through pipelines.

- Oil Refineries: They heat crude oil before it enters distillation towers for further processing.

- Gas Processing Plants: They heat natural gas, separating it from water and other impurities.

- Offshore Operations: In subsea pipelines, these heaters prevent hydrate formation, maintaining smooth oil flow.

Partnering with the right “circulation heaters manufacturer for oil and gas industry” or “circulation heater manufacturer for fluid heating” ensures these heaters are tailored for your specific process requirements.

Key Factors to Consider When Choosing a LOOM GRID Circulation Heater

Selecting the right heater is crucial for optimizing performance and ensuring long-term service life. Consider the following factors:

- Fluid Type: Different fluids have unique heating requirements. The heater should be compatible with the specific fluid used in your process.

- Temperature and Pressure Range: Ensure the heater can withstand the operational temperature and pressure conditions without compromising safety or efficiency.

- Corrosive Fluids: For fluids with corrosive properties, choose a heater that is built from corrosion-resistant materials.

- Watt Density: Ensure the heating element can deliver the necessary power for your process.

By carefully considering these factors and working with a reliable “circulation heaters manufacturer for oil and gas industry” or “circulation heater manufacturer for fluid heating,” operators can ensure that their LOOM GRID heater provides reliable, efficient, and safe heating for their oil and gas operations.

The Future of Circulation Heaters in the Oil and Gas Industry

Technological advancements continue to improve the capabilities of circulation heaters. Future innovations may include better heat transfer efficiency, extended temperature and pressure ranges, and enhanced corrosion resistance. By embracing these advancements and choosing a reliable “circulation heaters manufacturer for oil and gas industry,” companies in the oil and gas sector can increase operational efficiency, reduce downtime, and improve productivity.

LOOM GRID circulation heaters represent the future of industrial heating, offering unmatched performance, safety, and reliability for the most demanding applications. For the best results, always select the right “circulation heater manufacturer for fluid heating” or “circulation heaters manufacturer for oil and gas industry.”