A tubular heater is an electric heating device featuring a cylindrical metal casing, commonly made from stainless steel or other durable metals, which encloses a heating element. This element, usually a metal wire coil or ceramic rod, generates heat when an electric current passes through it. The metal casing not only protects the heating element but also aids in the even distribution of heat across the surface of the heater.

For those seeking a tubular heater manufacturer, these devices are integral in industrial processes and can be customized to meet specific heating needs. As a supplier of tubular heaters in India, we ensure that these products are tailored to various industrial requirements, including heating petroleum, chemicals, rubber, plastics, and more.

Applications of Tubular Heaters

Tubular heaters are predominantly used in industrial settings for a range of heating processes. They are essential in heating petroleum, chemicals, rubber, plastics, food products, and electronic components. Additionally, they are employed to heat air, water, oil, steam, and other media. Although they can be found in some domestic appliances like water heaters and air conditioners, their primary application remains in the industrial field.

For anyone looking for a tubular heater manufacturer or a supplier of tubular heaters in India, these devices are crucial for maintaining efficient and effective heating in various applications.

Functions of Tubular Heaters

- Precise Temperature Control: Tubular heaters are adept at maintaining specific temperatures, making them essential for temperature-sensitive processes like chemical reactions and biological incubation.

- Rapid Heating: Their efficient heat conduction allows them to quickly reach desired temperatures, suitable for applications that require swift heating.

- Energy Efficiency: The design of tubular heaters minimizes energy loss, reducing operational costs.

- Uniform Heating: They offer even heat distribution, ensuring a consistent temperature across the heated surface.

- Flexibility and Adaptability: Tubular heaters can be custom-shaped for diverse applications, including mould heating and pipe heating.

- Frost Protection: They prevent freezing of pipes and provide low-level heating in cold environments like greenhouses and storage areas.

Benefits of Tubular Heaters

- Precision: Tubular heating elements are known for their accuracy, offering advanced temperature control and effective heat management.

- Flexibility: They are adaptable to various industrial processes, making them a versatile choice for many heating needs.

- Durability: Designed to withstand high temperatures, tubular heaters offer long-lasting performance.

- Compact Size: Their small, portable design facilitates easy installation and maintenance.

- High Working Temperature: Capable of handling extreme temperatures, tubular heaters are ideal for high-temperature applications.

- Low Maintenance: With a robust, welded construction, they require minimal upkeep.

Types of Tubular Heaters

- Hot Runner Manifold Tubular Heater: Specially designed for plastic injection moulding, this heater ensures consistent plastic temperature during processing, optimizing production efficiency.

- Finned Tubular Heater: Equipped with fins to increase heat dissipation, used for heating air or gas in various applications.

- Screw Plug Tubular Heater: Features a screw plug for direct installation into containers, ideal for heating liquids like oil and water.

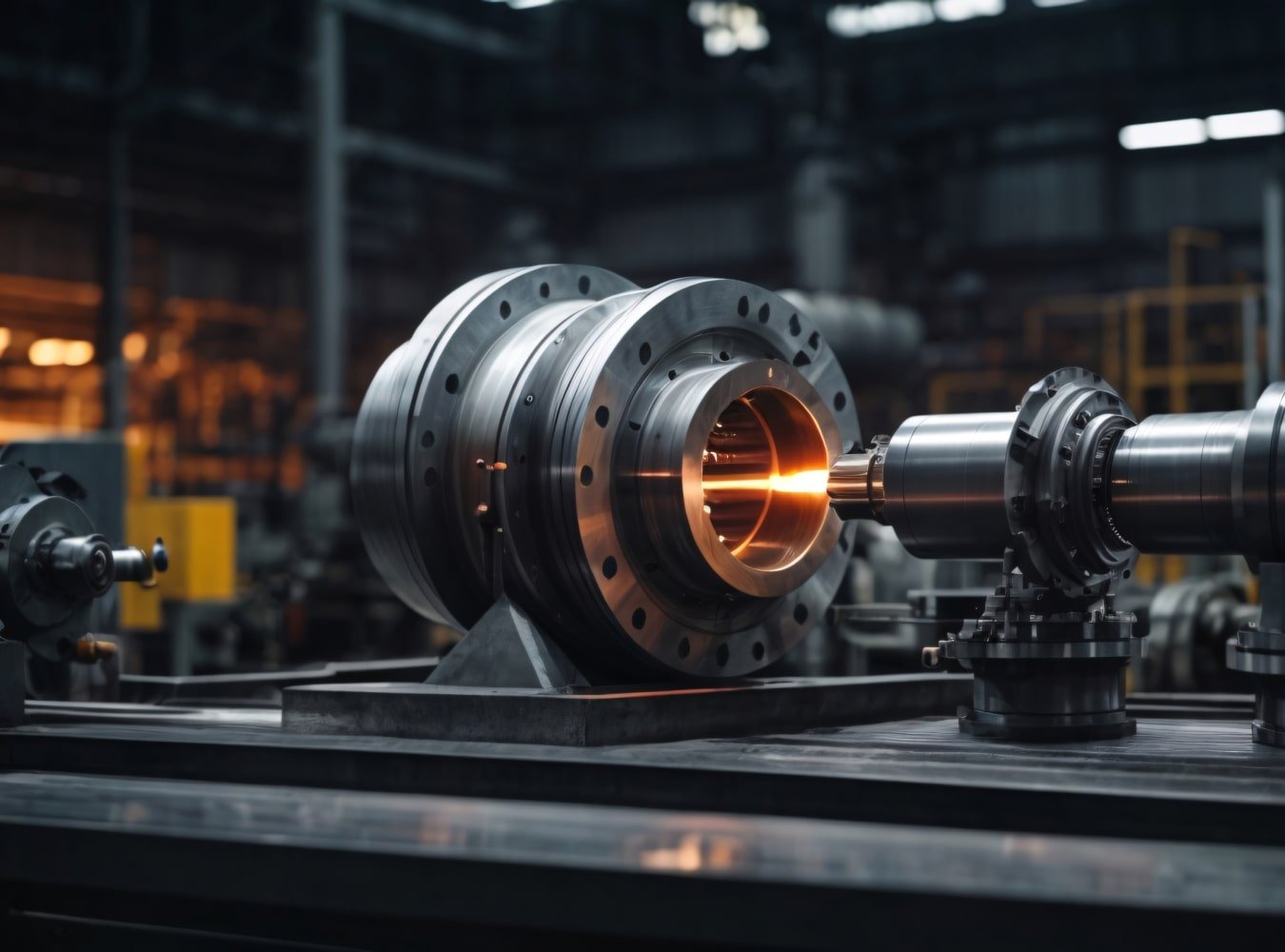

- Flanged Tubular Heater: Attached to a metal flange, this type is suited for large containers and industrial processes involving liquids and gases.

- Teflon Coated Tubular Heater: Coated with Teflon for corrosion and chemical resistance, this heater is used in industries dealing with corrosive substances.

Choosing the Right Tubular Heater

When selecting a tubular heater, it is crucial to consider factors such as the specific application, required temperature range, and environmental conditions. A reliable tubular heater manufacturer can provide guidance on the best heater for your needs. Additionally, working with a reputable supplier of tubular heaters in India ensures access to high-quality products tailored to various industrial requirements.

Innovations and Developments

Recent innovations in tubular heater technology focus on improving energy efficiency and enhancing performance. Modern tubular heaters now feature advanced materials and design improvements that increase their lifespan and reliability. Keeping up with these advancements can provide significant benefits in both operational efficiency and cost savings.

Conclusion

Tubular heaters are essential in various industrial applications due to their precise temperature control, energy efficiency, and adaptability. Whether you are looking for a tubular heater manufacturer or a supplier of tubular heaters in India, understanding the types, benefits, and innovations in tubular heaters will help you make an informed decision for your heating needs.